|

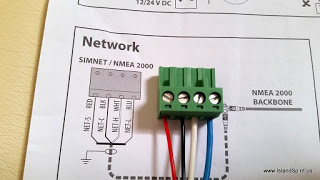

| …The new Digital Rudder Reference… |

Our second day of installing our new B&G Triton2 network is going well. Today, during the rain, we worked down below as working in the sail locker was not an option since it would rain into there and we did not want to deal with that. So we worked below decks and installed the digital rudder reference which uses a push rod to read the rotation and angle of the rudder. This information is sent to the autopilot computer, which then uses that information to help steer the boat.

|

| The Compass 9 aft the qtr berth in the stern |

Along with that, we installed the new nine-axis autopilot compass 9. In the words of B&G: With NMEA 2000® output, the Precision-9 Compass provides heading, Rate Of Turn (ROT), roll and pitch information to connected equipment including autopilot, instruments, radar, multifunction displays, and other navigational systems. So, with these two new digital tools, the new NAC-3 autopilot computer will really be smart. What we have seen with our old pilot is that a B&G autopilot computer learns the sea state and wave patterns and then, after a few minutes, the pilot will anticipate the waves and make the needed helm adjustments to keep on track. These pilots are so smart and we love sailing with ours. We actually sail 99% of the time under autopilot because it can do a much better job than we can for hours on end, day after day after day!

|

| Pettit Trinidad 75 Bottom Paint |

While we were working on our electronics installations, the Hinckley Yard Employee painted the bottom with our supplied Pettit Trinidad 75. This is the BEST PAINT money can buy! It is expensive because it has 75% cuprous oxide which means it is HEAVY and it is EXPENSIVE, copper is pricey. We bought this via our Port Supply account and it still was $260.00 per gallon, we needed two gallon$$$.

|

| The inboard position of Crew Triton2 |

The next task was placing the new Triton2 crew position cockpit display. Back in 1994 when this Island Packet 35 was shipped to Rock Hall MM for the 1993 Annapolis Boat Show, the dealer installed the Wind, Speed and Depth instruments in the front starboard side of the cockpit. This is an easy place to install instruments because the factory designed an open area here with a cabinet and a door giving easy access to this cavity. The problem is that every crew member that sits on starboard will eventually lean back against these three instruments making them impossible to see, plus it is hard on the instrument glazing.

The better place to install these is over the companionway but that makes for a difficult wiring run.

We decided to place one Triton2 in the same position but keep it as far inboard as possible. This will allow for the crew to lean back into this corner and NOT be on the face of the instrument. It will also allow for easy wire runs. We wanted one in this position because the Triton2 screens have 15+ screens of information and the crew will be scrolling through various screens. This keeps the instrument in easy reach, unlike over the companionway, so we placed it here.

|

| Using our dremel to cut the cockpit fiberglass |

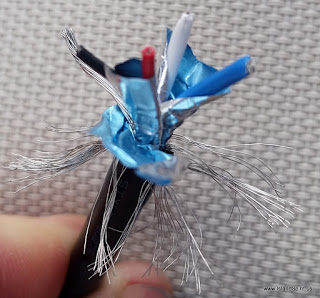

Using our onboard dremel tool and cordless drill, we first taped the template positioning the instrument into the lines of the cockpit. At first we wanted to install it plumb and vertical, but when we set it up like that, it looked odd. So we aligned the instrument to fit better into the lines of the cockpit. It worked.

We also made sure it was not too high like our last instruments which caused a problem when you would brace your palm onto the corner of the cockpit. Over all, we took out time laying this out, then the drilling and cutting was a breeze. It was far easier to cut into this fiberglass that it was to cut the 3/4″ plywood at the nav desk. So, our Triton2 crew position instrument is installed. Looking good.

Here are a few more photos of the process. Thanks for following along.

|

| Island Spirit with her new Pettit Trinidad 75 Bottom Paint |

|

We made sure this instrument was NOT too high

This allows us to brace ourselves against this corner. |

|

| After drilling 1/2″ corner holes, we cut out the square |

|

| These front tiny bezels of the Triton2 are very hard to separate |

|

| The bezel provides cover for the corner screws that install the Triton2 |

|

There it is, the finished install, looking good.

Pay no attention to the blue tape, we will fiberglass the holes |

|

| The corner position allows for bracing against this area |

|

The finished install. Now we need to fiberglass

the old holes and gelcoat that area |

Right NOW, we are ahead of schedule as we had this all planned for next week, the week of Nov 7. Here it is Nov 2 and it is the end of Day 2 installation and we are moving along. Tomorrow, if it is not raining, we will install the NAC-3 autopilot computer in the sail locker and connect the Type 1 Drive Ram, the 12 Volt Power and ground, the Rudder Reference, Compass9 and the GPS. Fun Fun Fun…..